Table Of Content

This analysis focuses on fine-tuning the design to ensure compatibility with manufacturing processes. For example, sharp internal corners may be rounded for convenient CNC machining. This phase is usually very iterative as each cycle of testing reveals new issues that require rework on the design. The movement from conceptual design to final design takes time and patience on the design team’s end. After production, engineers use rigorous testing to identify flaws and areas for improvement.

FMEA - Failure Modes and Effects Analysis

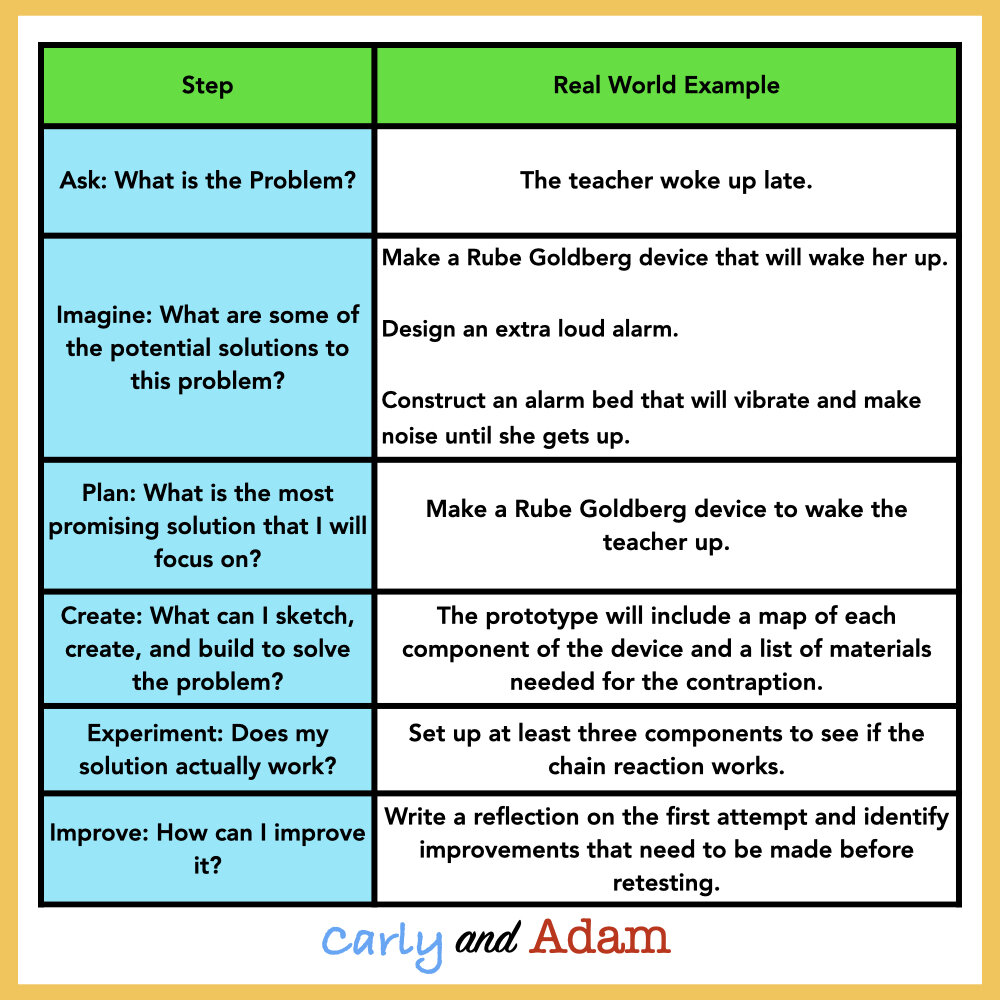

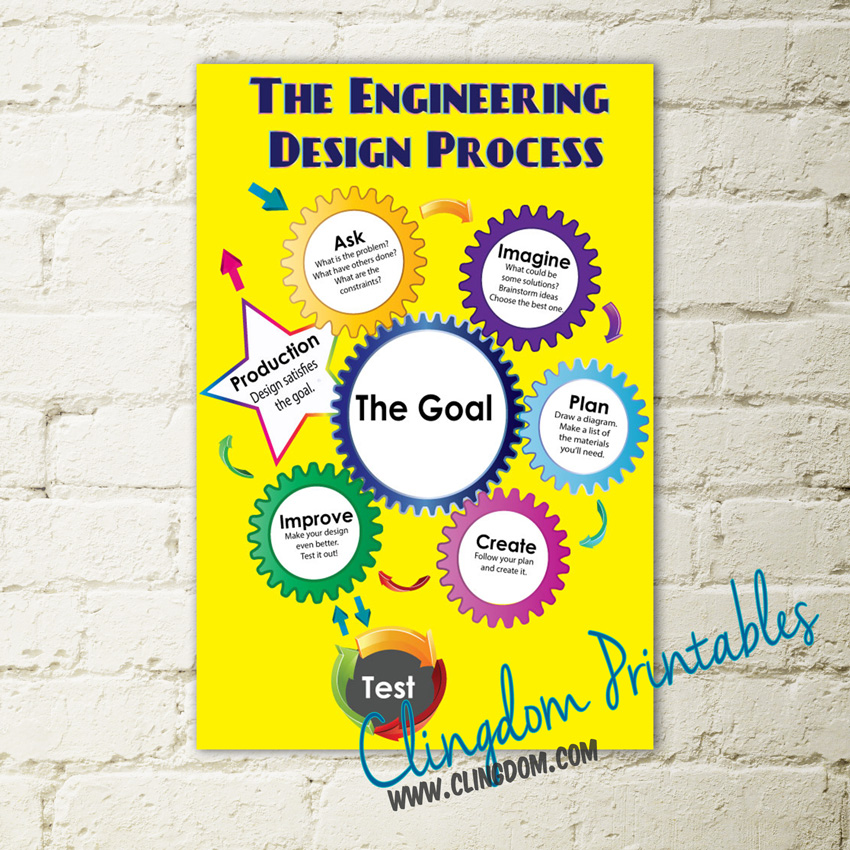

The engineering design process is a series of steps that engineers use to create solutions to problems. The engineering design process is iterative, meaning that engineers often repeat some or all of the steps several times to refine their solution. It is a critical component of the field of engineering, as it allows engineers to solve complex problems and create new products and technologies. Effective use of the engineering design process requires a strong understanding of engineering principles, scientific methods, and mathematical analysis. This activity introduces students to the steps of the engineering design process.

Concept generation

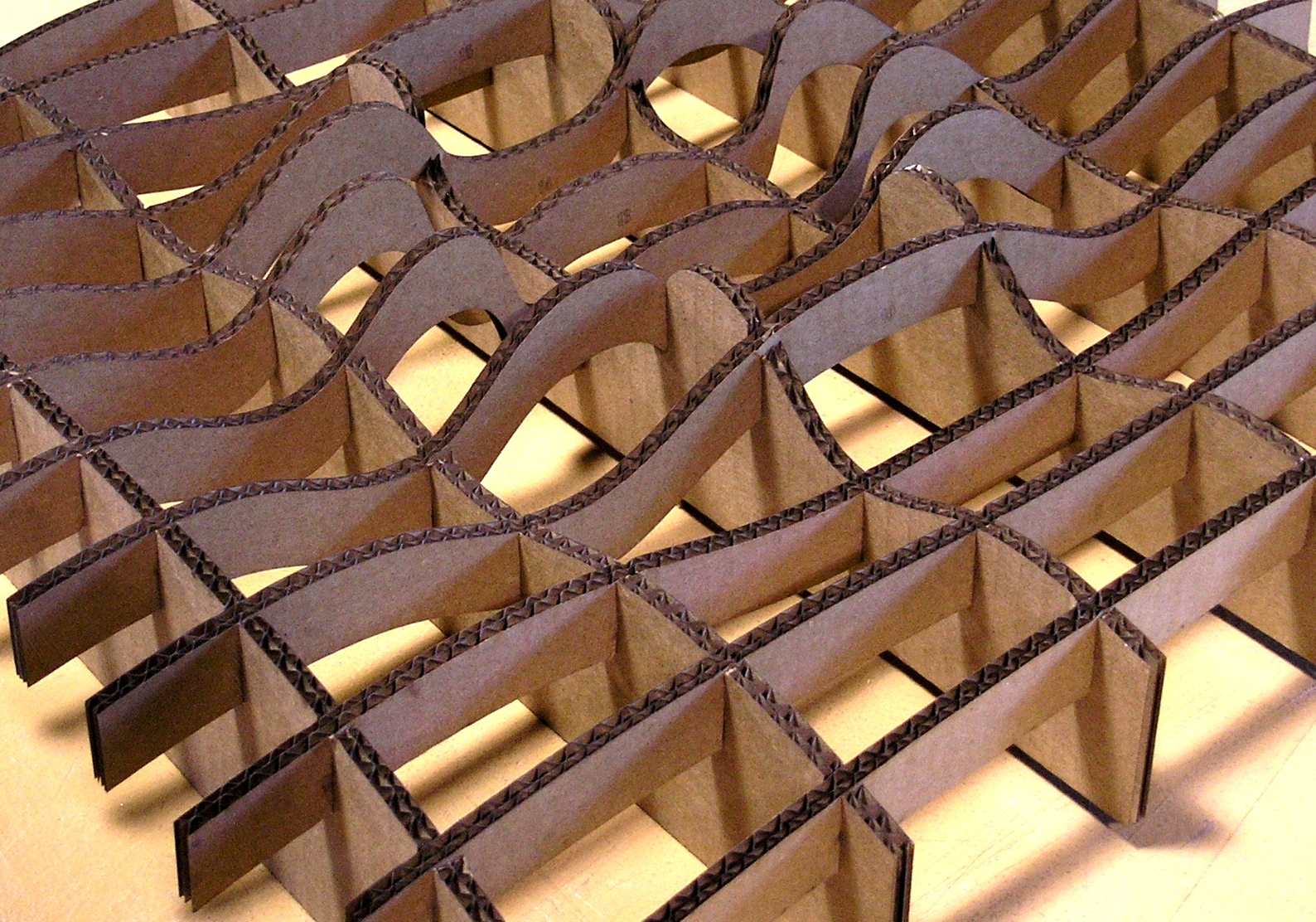

The prototyping stage sifts out such design flaws and allows designers to improve the design over iterations. The engineering design process is surely an outstanding methodology for working with design problems. The various engineering design process steps make the entire process very systematic and easy to follow, helping design teams organize their work in a better way. Therefore, it is common to work in a team of technical and non-technical people while working on an engineering design project.

Final Implementation and Deployment

The engineering design process was developed to create products that meet the needs of a target audience. By taking a structured approach to design that follows a defined path from problem to solution, engineers can research multiple ideas to determine which solution is most viable. While the process follows a defined pattern, it is iterative to yield the best results. Some steps may be completed out of order or repeated to eliminate issues or examine areas of concern. The engineering design process is commonly used on any project that requires designing, building, and testing a product. Mastering the engineering design process is a multifaceted journey that requires a blend of technical expertise, creativity, and strategic thinking.

How to Bring Environmental Design Optimizations into SOLIDWORKS - ENGINEERING.com

How to Bring Environmental Design Optimizations into SOLIDWORKS.

Posted: Tue, 17 Nov 2020 08:00:00 GMT [source]

Code, Data and Media Associated with this Article

They also create their own unique visualization through software called Processing. They learn how to use calibration and smoothing along the way to capture a better... Students are introduced to the biomechanical characteristics of helmets, and are challenged to incorporate them into designs for helmets used for various applications. Students learn how to control an Arduino servo wirelessly using a simple phone application, Bluetooth module and an Android phone. Students gain practice in Arduino fundamentals as they design their own small-sized prototype light sculptures to light up a hypothetical courtyard. They program Arduino microcontrollers to control the lighting behavior of at least three light-emitting diodes (LEDs) to create imaginative light displ...

How to Design for Sustainable Manufacturing - ENGINEERING.com

How to Design for Sustainable Manufacturing.

Posted: Wed, 23 Mar 2022 07:00:00 GMT [source]

Summary of Step B – Develop Ideas

In the context of engineering design, the design team forwards its work to the production department. The production team then prepares a manufacturing plan based on factors like deadlines, chosen manufacturing processes, DFM analysis, quality and quantity requirements, and material availability. In a common engineering design process example, these requirements include targets like product weight, volume, useful life, user safety, and manufacturing costs.

Resources

You may wish to consider further solutions to compare the potential outcomes and find the best approach. This will involve repeating some of the earlier steps for each viable idea. By embracing best practices, leveraging key tools, and committing to ongoing professional development, you can elevate your engineering projects to new levels of excellence.

Students conclude this introductory step with a focused summary of the purpose of their role in the engineering design process. Why use project-based learning (PBL) with the engineering design process (EDP)? STEM-based instruction and learning guided by EDP go hand-in-hand with PBL. Students go deeper into concepts and content to enhance their academic learning with a problem-to-be-solved in focus.

Mastering the Engineering Design Process: A Step-by-Step Guide

Students design and build a mechanical arm that lifts and moves an empty 12-ounce soda can using hydraulics for power. Small design teams (1-2 students each) design and build a single axis for use in the completed mechanical arm. Students' understanding of how robotic color sensors work is reinforced in a design challenge involving LEGO® MINDSTORMS® robots and light sensors. Working in pairs, students program LEGO robots to follow a flashlight as its light beam moves around.

Indeed, engineered products may be very complex, and the design of such products may require that a design team make hundreds or thousands of decisions. They provide a framework in which the team decision-making is made explicit and the decision process can be well documented. They also reduce the likelihood that important issues will be forgotten or overlooked. If you have trouble coming up with a design challenge, it helps to brainstorm with the students. Choose a topic (for example, prosthetics), and make a list on the board of potential design/build projects that relate to the topic. Back to our engineering project — our final step today is to develop a project definition within each of our design teams.

Students follow the steps of the engineering design process to design an improved smartphone case. As if they are materials engineers, they evaluate how to build a smartphone case and study physical properties, chemical properties, and tessellations. Students further their understanding of the engineering design process (EDP) while applying researched information on transportation technology, materials science and bioengineering.

Often it is made with different materials than the final version, and generally it is not as polished. Prototypes are a key step in the development of a final solution, allowing the designer to test how the solution will work. Students are challenged to design and build wind chimes using their knowledge of physics and sound waves, and under given constraints such as weight, cost and number of musical notes it must generate. Students explore energy efficiency, focusing on renewable energy, by designing and building flat-plate solar water heaters.

No comments:

Post a Comment